In less than two months, the world has turned upside down for just about everyone as the coronavirus has shut down operations, shifted concerns and fired up creativity.

This has been true, too, for Naveen Jindal School of Management faculty – even those far removed from the frontlines of the COVID-19 fight.

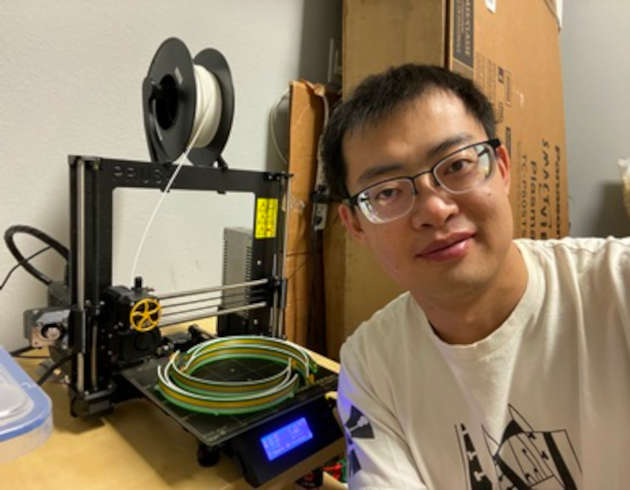

Dr. Bin Hu, a Jindal School associate professor in operations management, found that his 3D printer, purchased as a hobby to address his geeky side, has become part of The University of Texas at Dallas communitywide effort to fend off the virus.

Using an open-source online design, Hu has been printing the headband part of face shields being worn by about 50 staffers in campus Housing and Building Operations department. Dr. J.C. Stoner, associate director of Housing Operations, said that after Hu’s headbands were delivered, he sourced 20 mil clear plastic and had his staff assemble the shields. The cost works out to be about $2 per shield, about the same price of placing a bulk order online. Delivery from online sources, however, remains uncertain.

Providing an Essential

Stoner said maintenance and housekeeping staff are issued shields, which are easy to clean. “Throughout the pandemic, they have been essential to staff cleaning public spaces and entering occupied rooms to respond to emergency work orders,” he said. “We were unable to get shields due to them being on backorder, but they became a reasonable option when Dr. Hu approached us.”

It appears medical experts find it an excellent solution. In an April 29, 2020, Journal of the American Medical Association story, authors noted that in a simulation study of influenza virus, face shields reduced viral exposure by 96 percent when worn within 18 inches of a cough. The authors said: “While medical masks have limited durability … face shields can be reused indefinitely and are easily cleaned with soap and water, or common household disinfectants.”

Hu and Stoner connected because of a UT Dallas staff email. “I had learned of the printable shield design more than a month ago,” Hu said, “but I didn’t know where to source the clear shield or the rubber band, and didn’t know anyone who needed it.”

Then, in early April, a campus-wide email, forwarded to JSOM faculty and staff by Susan Scott, an administrative assistant in the Jindal School Dean’s Office, sought volunteers to sew masks. Hu said he started thinking through the face shield problem again. “I realized I could source thick stationery clear covers as shield sheets and link hair rubber bands … to make the face shield.” Through the email chain, Hu and Stoner were connected.

He Started With Trinkets

Hu said that in the past, he has mostly printed things to amuse himself, family members or friends. “My office is filled with interesting but useless printed trinkets,” he said. “When my daughter had weekly show-and-tell assignments, I printed an object for each week’s theme. Last year on March 14, I went to the Pi Day event at Math@UTD with 3D-printed math objects and gave a fun talk.

“Occasionally I also design and print simple home-improvement objects,” he said. “When I found out that my couch was too low for my vacuum robot to go underneath, I designed and printed couch riser blocks. I also helped a friend customize a disc for her spaghetti maker so she can make star- and heart-shaped spaghetti.”

The Academic Side of 3D Printing

There is also an academic purpose to Hu’s 3D Prusa printer. “To begin with, I printed trophies for in-class activities,” he said. “But more seriously, it introduced me to a very different type of supply chain and manufacturing. In fact, I have written a research paper inspired by the Prusa printer. The paper is now under second round review at Management Science. … I also wrote a teaching case based on the Prusa story, although I haven’t had a chance to teach it.”

He is on the lookout for more 3D printing-inspired research ideas, including its role in the COVID-19 crisis. “Overall, with the fun I’ve had with it, the face shields made, and the paper and teaching case it inspired, I’d say my 3D printer was quite a worthy investment.”

Hu has not stopped his philanthropic shield-making efforts either. He is now printing headbands for a local off-campus student group that is helping stock hospitals, organize fundraisers and delivering crowd-sourced personal protective equipment to those in need.

As he said: “Pretty cool!”